Relativity Space wins $8.7 million U.S. Air Force contract for additive manufacturing research

WASHINGTON — Relativity Space, a company that builds launch vehicles using 3D printing technology, has secured an $8.7 million contract with the U.S. Air Force Research Laboratory (AFRL) to explore real-time flaw detection in additive manufacturing.

Real-time flaw detection in 3D printing is the ability to identify defects as parts are being printed. This is an important technology as additive manufacturing works by laying down thin layers of material on top of each other so each layer adds to the potential for imperfections.

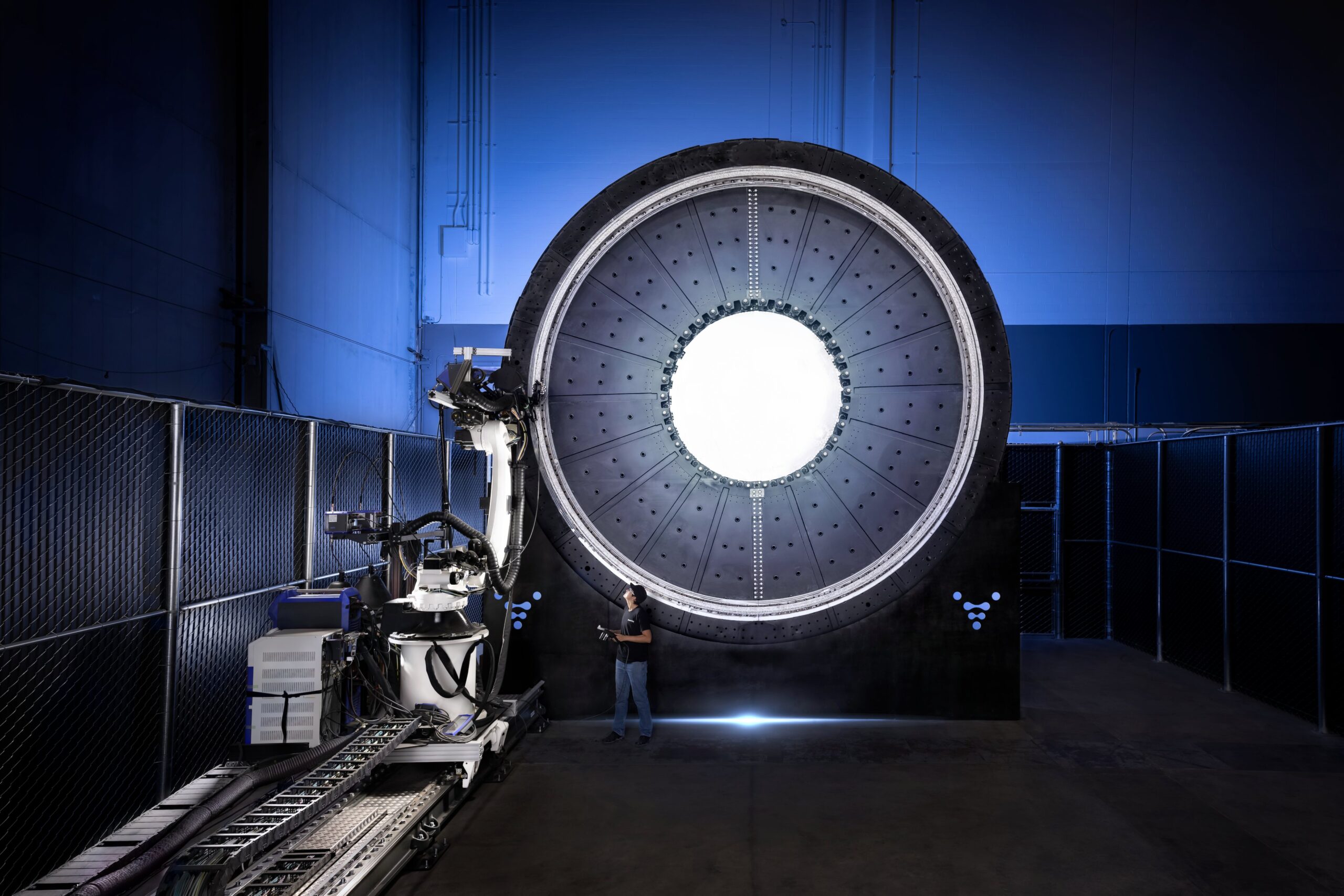

The two-year research contract is from AFRL’s Materials and Manufacturing Directorate at Wright-Patterson Air Force Base, Ohio. The work for this project will be done at Relativity’s factory in Long Beach, California, using the company’s Stargate 3D printing platform, known for its large-scale metal printing capabilities.

“This effort with Relativity Space is in response to a congressional demand signal,” Adam Hicks, a physicist at AFRL’s Materials and Manufacturing Directorate, said in a statement to SpaceNews.

Legislative mandate

Congress in the National Defense Authorization Act directed the Defense Department to study ways to leverage additive manufacturing to accelerate the production of aerospace components and vehicles. Lawmakers also mandated that DoD establish a network of domestic suppliers to help evaluate these technologies.

Hicks said AFRL will work with Relativity on real-time flaw detection in large-format additive manufacturing. “The intent is to explore various in-situ process monitoring and post-build non-destructive evaluation techniques, along with advanced robotics, automation and digital enterprise tools,” he said.

Non-destructive evaluation techniques are used to ensure the quality and integrity of the final product by examining the structure of a part without damaging it.

“Relativity Space will develop and prove a real-time flaw detection system which will detect, localize and classify defects during the print process,” Hicks said. “This data will then be aggregated, enabling a true digital thread.”

In aerospace engineering, a digital thread is the equivalent of a central nervous system for the entire lifecycle of a platform such as an aircraft — from design all the way to disposal. A digital thread is established through data that bridges the gap between various stages of an aircraft’s existence.

Experts point out that real-time flaw detection will be crucial for larger-scale adoption of additive manufacturing in spaceflight and other demanding applications.

Relativity Space is one of several companies pioneering the use of additive manufacturing in aerospace. The technology offers advantages such as reduced lead times, increased design flexibility and lighter weight parts. However, ensuring the quality of additively manufactured parts remains a key challenge.

Related

Read the original article here